Blog

The Ultimate Checklist for Choosing the Best Mini CNC Mill for Your Business Needs

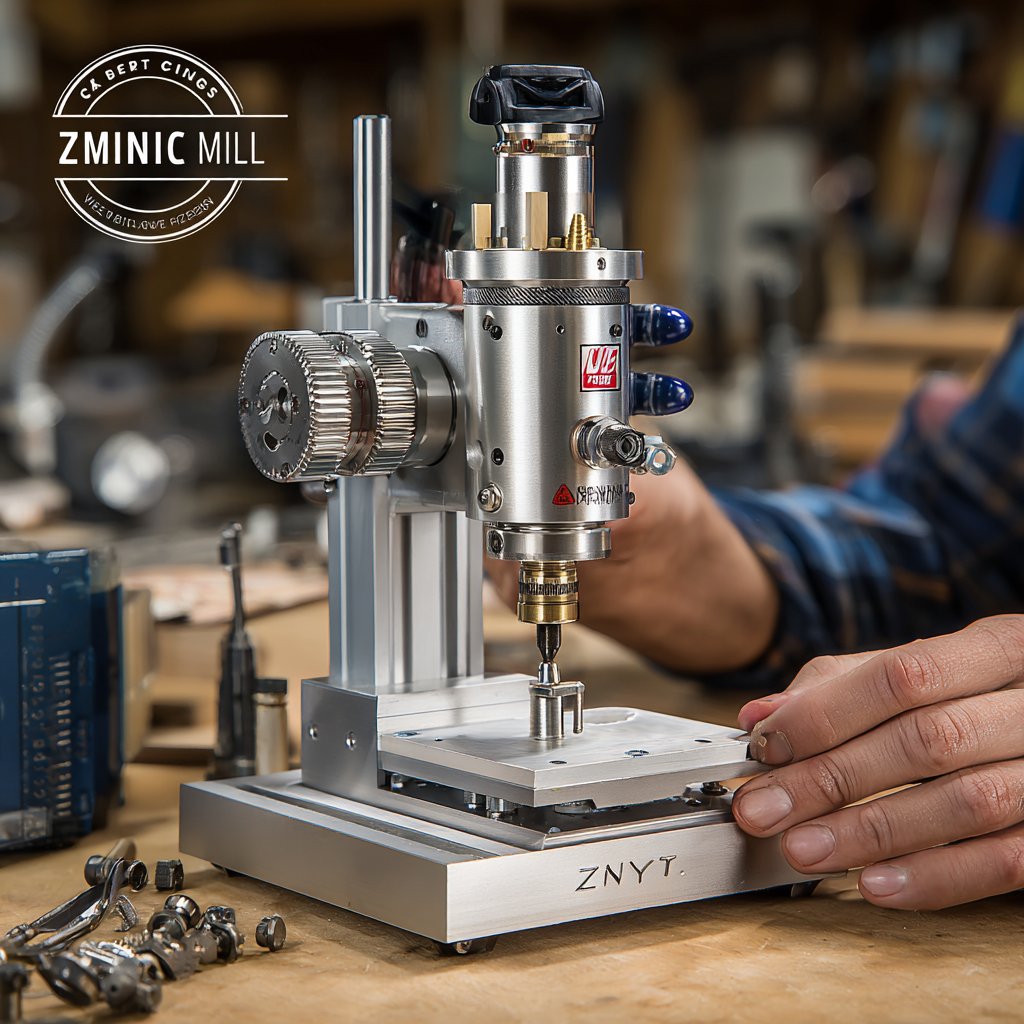

In today’s rapidly evolving manufacturing landscape, choosing the right equipment is crucial for business success, particularly when it comes to precision machining. Among the various options available, mini CNC mills have emerged as a popular solution for small to medium-sized enterprises looking to enhance their production capabilities. According to a recent report by MarketsandMarkets, the CNC machine market is projected to reach $100 billion by 2025, with a significant portion attributed to mini CNC mills due to their compact size and versatility. These machines not only offer precision and efficiency but also facilitate ease of use for various materials, which is essential in today’s competitive market. This blog aims to provide a comprehensive checklist to help businesses make informed decisions when selecting the best mini CNC mill tailored to their specific needs.

Understanding Your Business Requirements for a Mini CNC Mill

When considering the purchase of a mini CNC mill for your business, the first step is to clearly understand your specific requirements. Analyzing your production needs is essential. Are you looking to create intricate designs or handle heavier materials? Identifying the type of projects you will be undertaking can guide your decision on the necessary specifications of the machine, such as spindle speed, cutting power, and work area size.

Additionally, it's important to consider the ease of use and the learning curve associated with the machine. If your team is not experienced with CNC technology, opting for a user-friendly model with comprehensive support may be beneficial. Also, think about the software compatibility, as this will impact how well the machine integrates with your existing processes. By aligning the features of a mini CNC mill with your business objectives, you ensure that your investment will meet both your immediate and long-term needs.

Key Features to Consider When Selecting a Mini CNC Mill

When selecting a mini CNC mill for your business needs, it’s essential to focus on key features that can significantly impact your productivity and efficiency. One of the primary considerations is the machine's accuracy and precision. Look for mills that offer a high-resolution spindle and a robust feedback system. These features will ensure that your projects meet stringent quality standards, especially if you are working with intricate designs or durable materials.

Another critical factor is the size and weight of the mini CNC mill. A compact and lightweight machine can easily fit into small workshops while still delivering superior performance. However, ensure that it also has enough workspace and can accommodate the types of projects you plan to undertake. Additionally, consider the software compatibility and ease of use. A user-friendly interface can streamline the learning curve and enhance operational efficiency, allowing you to quickly adapt the mill for various applications. By carefully assessing these features, you’ll be better equipped to choose the mini CNC mill that best meets your specific business requirements.

The Ultimate Checklist for Choosing the Best Mini CNC Mill for Your Business Needs - Key Features to Consider When Selecting a Mini CNC Mill

| Feature | Description | Importance Level |

|---|---|---|

| Cutting Area | The maximum size of the workpiece that can be machined. | High |

| Spindle Speed | The maximum RPM of the spindle, affecting machining efficiency. | Medium |

| Drive System | Type of drive (e.g., stepper, servo) impacting precision and force. | High |

| Ease of Use | The user-friendliness of the software and controls. | Medium |

| Material Compatibility | Types of materials that can be machined (e.g., metals, plastics). | High |

| Price | Initial cost of the mill and value for features offered. | High |

| Customer Support | Availability and quality of support services post-purchase. | Medium |

| Footprint | The physical space required for installation and operation. | Low |

Evaluating Supplier Credentials and Industry Experience

When selecting a mini CNC mill for your business, evaluating supplier credentials and industry experience is paramount. A reputable supplier will typically showcase a history of successful projects, quality certifications, and customer testimonials. Look for suppliers who have been in the industry for several years, as this often indicates a level of expertise and reliability in meeting diverse machining needs.

Tip: Always ask potential suppliers for case studies or references from previous clients. This not only gives you insight into their workmanship but also helps you gauge their problem-solving abilities and understanding of customer requirements. A supplier with a robust portfolio will demonstrate their capacity to adapt and innovate within the CNC milling sector.

In addition, consider the extent of the supplier's industry involvement. A vendor actively engaged in trade shows, forums, and continuous education is likely to stay ahead of technological advancements and market trends. This knowledge can translate into better equipment and support for your operations.

Tip: Look for suppliers who offer comprehensive training and support services. This ensures that you won't just receive a product but also the knowledge and assistance necessary to operate your CNC mill effectively, promoting efficiency and productivity in your business.

Comparing Pricing Structures and Warranty Options

When considering a mini CNC mill for your business, understanding the pricing structures and warranty options available is essential. According to a report by Technavio, the global CNC machine market is projected to grow by approximately $2 billion from 2021 to 2025, highlighting the industry's increasing demand and competitiveness. Mini CNC mills typically range from $2,000 to $10,000, depending on features, precision, and brand reputation. Businesses must weigh their budget against the return on investment, factoring in the potential productivity gains and material cost savings.

Warranty options often play a crucial role in the decision-making process. A robust warranty can mitigate risks associated with equipment failure, which can lead to costly downtime. Many manufacturers offer warranties ranging from one to several years. For instance, some brands provide a three-year warranty, which is crucial for businesses that rely heavily on their CNC mills for continuous production. It’s advisable to thoroughly review what each warranty covers, including parts, labor, and on-site service, to ensure that your investment is protected against unforeseen issues, thereby safeguarding long-term business efficiency.

The Ultimate Checklist for Choosing the Best Mini CNC Mill

This chart compares key specifications to consider when choosing a mini CNC mill for your business needs. It focuses on pricing, warranty duration, speed, and precision, helping you to make informed decisions.

Finding Reliable Customer Support and After-Sales Service

When choosing a mini CNC mill for your business, one crucial factor often overlooked is the quality of customer support and after-sales service. The entire customer experience is shaped not only by the product itself but also by how a company engages with its clients throughout the buying journey and beyond. From initial inquiries to technical support after purchase, reliable customer service can significantly enhance the perceived value of your investment in a new CNC mill. A manufacturer that prioritizes customer experience can transform daunting challenges into manageable solutions, ensuring that users feel supported every step of the way.

Excellent after-sales service differentiates successful companies in today’s competitive landscape. It fosters long-term relationships and encourages customer loyalty, as clients are more likely to return to a brand that values their ongoing needs. By nurturing this connection and providing prompt, helpful support, businesses create an environment where customers feel heard and appreciated. As you evaluate options for mini CNC mills, prioritize those who offer robust after-sales support—this factor could ultimately decide your business's operational efficiency and success.