Blog

Choosing the Top 7 Features of the Best CNC Milling Machine Manufacturers

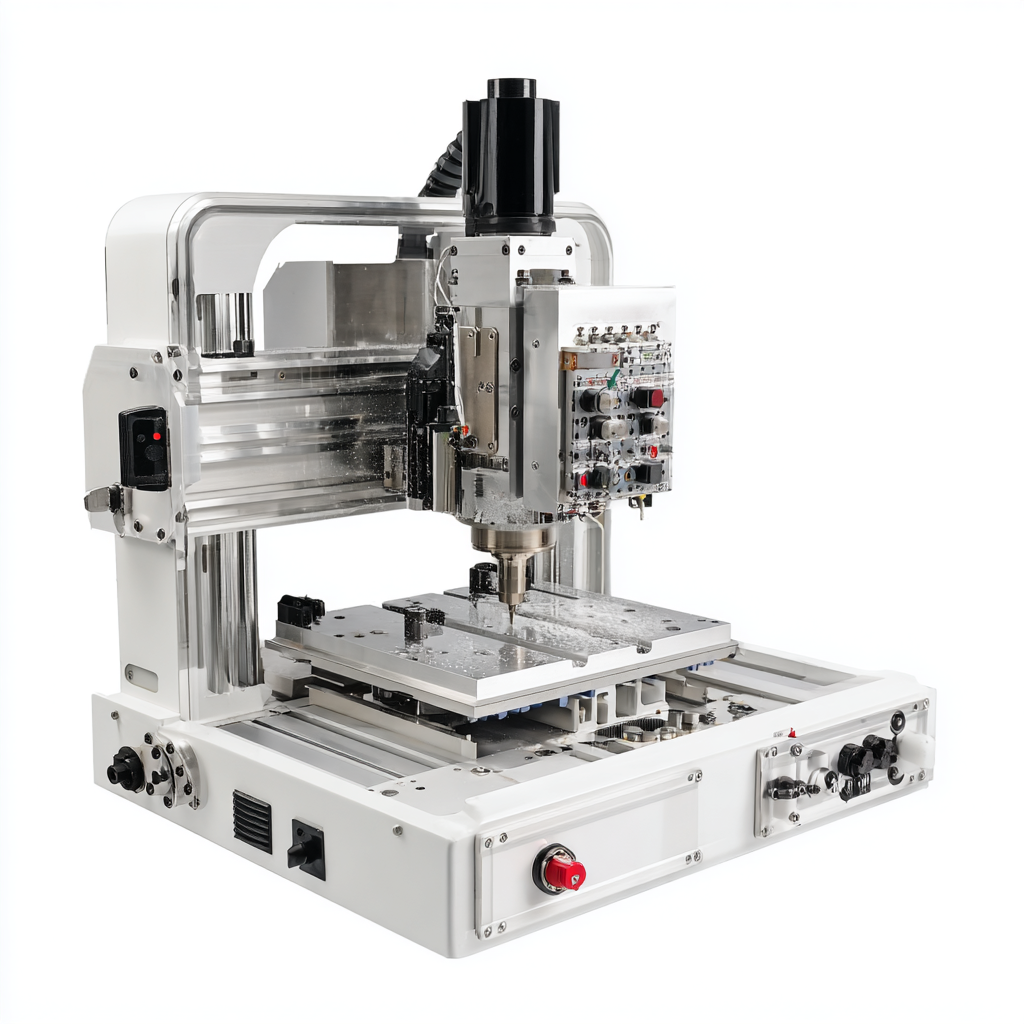

In the rapidly evolving landscape of modern manufacturing, CNC milling machines have become quintessential tools that enhance precision and efficiency across various industries. According to a recent report by Research and Markets, the global CNC machining market is expected to reach $100 billion by 2025, driven by the increasing demand for automated processes and advanced manufacturing solutions. However, selecting the best CNC milling machine manufacturer can be a daunting task due to the myriad of options available, each varying significantly in features, quality, and reliability. This blog will delve into the top seven features to consider when choosing a CNC milling machine manufacturer, addressing common problems faced in the industry and guiding you towards making an informed decision that aligns with your production needs.

Key Factors to Evaluate CNC Milling Machine Manufacturers

When evaluating CNC milling machine manufacturers, several key factors come into play, particularly for industries that require high reliability, such as aerospace. One of the foremost considerations is the manufacturer's ability to deliver precision and surface integrity in critical structural components. This is vital because even minor deviations can significantly affect the performance and safety of aerospace applications. A manufacturer that employs advanced technology and rigorous quality control processes is essential for ensuring that the machined parts meet stringent aerospace standards.

Another important factor is the range of materials that the manufacturer can work with. Aerospace components often require a variety of materials, including high-strength alloys and composites. A top CNC milling machine manufacturer should demonstrate expertise across multiple material types and offer flexible machining solutions to accommodate diverse project requirements. Additionally, after-sales support and service are crucial; manufacturers should provide comprehensive support to address any issues that may arise post-installation, ensuring continued reliability and efficiency of the equipment in demanding manufacturing environments.

Understanding the Importance of Precision in CNC Machining

In the world of CNC machining, precision is not just a feature; it is a fundamental necessity. The ability to create intricate and accurate components from various materials requires sophisticated machinery that adheres to strict tolerances. Manufacturers rely heavily on CNC milling machines to achieve this level of precision, as even the slightest deviation can lead to significant defects, increased waste, or production delays. This underscores the importance of selecting machines from reputable manufacturers known for their commitment to quality and technology.

When evaluating CNC milling machine manufacturers, it’s crucial to consider their emphasis on precision and reliability. Cutting-edge technology such as advanced control systems, high-speed spindles, and robust tooling can significantly enhance performance. Furthermore, manufacturers should offer rigorous testing and calibration processes to ensure that their machines consistently meet the desired specifications. By prioritizing precision in CNC machining, manufacturers can not only improve their operational efficiency but also deliver superior products that meet or exceed customer expectations.

Assessing the Range of CNC Machines Offered by Manufacturers

When choosing a CNC milling machine, the range of machines offered by manufacturers is a critical aspect to consider. According to a report by MarketsandMarkets, the CNC machine market is projected to grow from $71.1 billion in 2021 to $102.96 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.7%. This growth is largely driven by advancements in automation and the increasing demand for precision manufacturing across various industries, such as aerospace, automotive, and medical device production.

Leading CNC milling machine manufacturers offer a diverse lineup of machines designed to meet different operational needs. For instance, high-speed milling machines, multi-tasking machines, and 5-axis CNC mills are among the top products that enhance productivity while providing increased accuracy. A comprehensive selection not only allows for versatility in machining operations but also ensures that manufacturers can cater to clients with specific requirements. The ability to provide various capabilities, such as precision gear cutting or thermal spraying, enables manufacturers to strengthen their market position and appeal to a broader customer base.

Evaluating Customer Support and Service from CNC Milling Providers

When selecting a CNC milling machine manufacturer, evaluating customer support and service is vital. In today's fast-paced manufacturing environment, companies cannot afford downtime caused by technical issues or inadequate support. A manufacturer that provides responsive and effective customer service not only ensures operational efficiency but also fosters trust and long-term collaboration. This is particularly important for businesses that have experienced the need to reassess their suppliers and seek true partnerships to achieve mutual success, as seen in various industries, including medical device manufacturing.

In an era where the complexity of projects increases, manufacturers must prioritize a proactive approach to customer support. This includes timely communication, knowledgeable staff, and comprehensive support systems that facilitate problem-solving. A strong commitment to customer care can distinguish one CNC milling provider from another, making it a crucial feature for companies looking to build lasting relationships and ensure smooth operations. As the market evolves, manufacturers that excel in service quality are likely to become preferred partners, aligning with the industry's growing emphasis on collaboration and shared success.

Choosing the Top 7 Features of the Best CNC Milling Machine Manufacturers - Evaluating Customer Support and Service from CNC Milling Providers

| Feature | Importance Level | Customer Support Rating | Service Availability |

|---|---|---|---|

| Technical Expertise | High | 4.8/5 | 24/7 Support |

| Response Time | Medium | 4.5/5 | Within 1 Hour |

| Training Programs | High | 4.7/5 | Available on Request |

| Parts Availability | High | 4.6/5 | Same Day Shipping |

| Customization Options | Medium | 4.4/5 | On Request |

| Warranty Coverage | High | 4.9/5 | 2 Years |

| User Reviews | High | 4.7/5 | Readily Available |

Innovative Technologies and Features in Top CNC Milling Machines

When selecting the best CNC milling machines, innovative technologies and features play a pivotal role in enhancing productivity and precision. Leading manufacturers have embraced advancements such as intelligent automation, which reduces manual intervention and streamlines the machining process. This technology allows for real-time monitoring and adjustments, ensuring that the machines operate optimally while minimizing human error. The integration of machine learning algorithms also enables predictive maintenance, which helps in identifying potential issues before they lead to downtime, thereby increasing overall efficiency.

Moreover, the flexibility of tooling options is another noteworthy feature in top CNC milling machines. Manufacturers are now offering advanced modular tooling systems that allow users to quickly swap out tools or adapt cutting parameters based on different materials and designs. This adaptability not only enhances operational efficiency but also opens up new possibilities for complex tasks, enabling manufacturers to tackle diverse projects without needing extensive retooling. As the industry continues to evolve, these innovative features will remain essential for businesses striving to stay competitive in the ever-changing landscape of CNC machining.