Blog

Exploring the Unique Features and Applications of Best CNC Turning Products in Modern Manufacturing

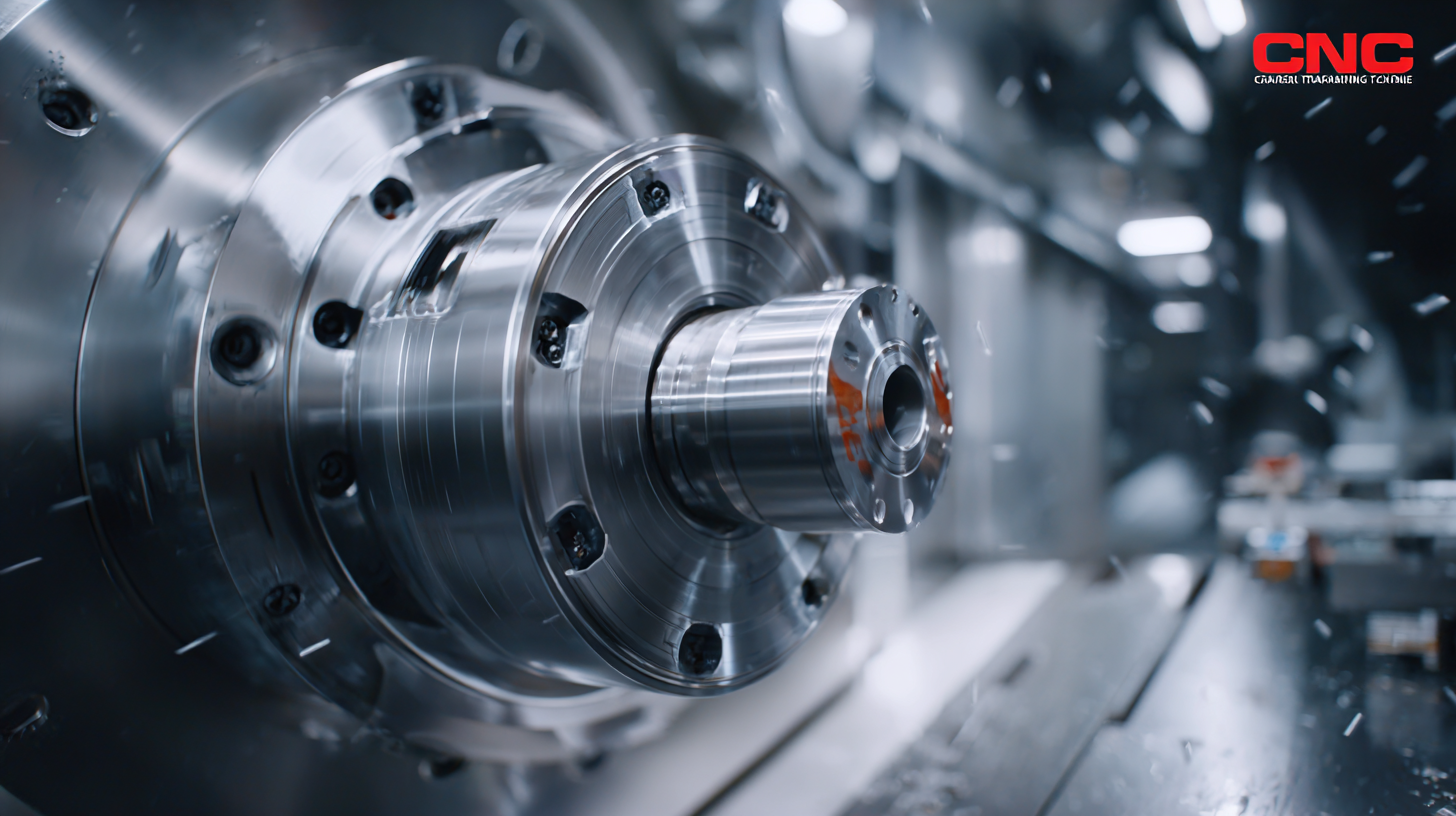

In the ever-evolving landscape of modern manufacturing, CNC turning technology stands at the forefront, redefining productivity and precision. According to a recent report by Grand View Research, the global CNC machine market is projected to reach $100 billion by 2025, with CNC turning products playing a pivotal role in this growth due to their efficiency and versatility. As industries range from aerospace to automotive increasingly rely on CNC turning for complex part fabrication, understanding the unique features and diverse applications of these advanced products becomes essential. This blog aims to explore the distinctive attributes of the best CNC turning solutions available today, highlighting their significance in streamlining manufacturing processes and enhancing operational capabilities in various sectors.

Key Advantages of CNC Turning Machines in Precision Manufacturing

CNC turning machines have emerged as vital tools in precision manufacturing, driven by their ability to produce intricate components with high accuracy and efficiency. The global CNC machining and turning centers market is estimated to reach USD 25.99 billion in 2023, with a robust projected growth rate of 6.6% CAGR from 2024 onwards. This growth highlights the increasing reliance on these technologies to meet the demands for precision and speed in various industries.

One of the key advantages of CNC turning centers is their exceptional speed and accuracy, exemplified by advanced twin-spindle models that are revolutionizing bar-fed machining applications. These machines not only enhance production capabilities but also allow manufacturers to optimize their workflows, reducing cycle times and improving overall output. As the demand for high-precision components escalates, manufacturers are increasingly integrating CNC turning technologies into their operations, with the CNC machine tools market expected to grow significantly, driven by the rising need for multi-axis machining centers and automation features that redefine the market landscape.

Understanding the Role of CNC Turning in Streamlining Production Processes

CNC turning technology plays a pivotal role in modern manufacturing, streamlining production processes with enhanced precision and efficiency. As the global CNC machine market is projected to soar from $101.22 billion in 2025 to $195.59 billion by 2032, this growth signifies a significant shift towards automating manufacturing operations. Notably, the CNC machining and turning centers market size was estimated at $25.99 billion in 2023, with expectations to expand at a CAGR of 6.6% from 2024 onwards. Such growth underscores the increasing reliance on CNC turning to meet the demands of high-volume production while ensuring meticulous accuracy.

Automation in CNC machining further amplifies these advantages by enabling companies to enhance precision and productivity. The integration of advanced automation technologies allows manufacturers to achieve consistent quality and significantly lower cycle times. This procedural optimization is crucial in an industry where rapid advancements in technology are imperative for maintaining competitive advantage. As CNC turning continues to evolve with innovative tools and software, manufacturers are better equipped to master challenges involving chip control and material efficiency, ultimately contributing to economic sustainability in production processes.

Applications of CNC Turning in Modern Manufacturing

Comparative Analysis: CNC Turning vs. Traditional Turning Techniques

CNC turning technology has significantly transformed the manufacturing landscape, offering precision and efficiency that traditional turning methods struggle to match. According to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.5 billion by 2026, driven by the demand for automation and reduction in human error. In contrast, traditional turning techniques often rely heavily on operator skill and experience, which can lead to inconsistencies and longer production times.

CNC turning technology has significantly transformed the manufacturing landscape, offering precision and efficiency that traditional turning methods struggle to match. According to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.5 billion by 2026, driven by the demand for automation and reduction in human error. In contrast, traditional turning techniques often rely heavily on operator skill and experience, which can lead to inconsistencies and longer production times.

One key difference lies in the adaptability of CNC turning machines. These machines can handle complex geometries and varied materials with ease. A study from Deloitte highlighted that manufacturers utilizing CNC turning can increase their operational efficiency by up to 40%. This flexibility allows for quick reprogramming to accommodate changes in design, making CNC a preferable choice for modern manufacturing needs.

Tips: When selecting a CNC turning machine, consider factors such as compatibility with CAD/CAM systems and the machine's ability to handle multi-axis operations. Additionally, investing in training for your workforce can substantially enhance productivity and machine utilization. Embracing CNC technology requires a balance between capital investment and the potential return in efficiency and quality improvements.

Exploring Material Compatibility for Enhanced Efficiency in CNC Turning

In the realm of modern manufacturing, CNC turning products have become pivotal for enhancing efficiency and precision. One area of exploration is the material compatibility during the CNC turning process. The integration of advanced materials, such as nanocellulose derived from agricultural biowaste, presents exciting opportunities. This sustainable material not only offers biocompatibility but also enhances the functional properties of components, making it a strong candidate for various biomedical applications.

Tips for selecting materials: When choosing materials for CNC turning, consider their mechanical properties, biocompatibility, and sustainability. Utilizing materials like nanocellulose can lead to innovative workflows and reduce environmental impact. Additionally, understanding the chemical and physical properties of the materials can inform better decisions regarding functionalization, which is essential for enhancing interfacial interactions and overall performance in CNC machined parts.

Moreover, recent advancements in CNC technology allow for improved processing techniques that can be tailored to specific materials. By focusing on the unique characteristics of each material, manufacturers can achieve optimal performance. This highlights the importance of researching and selecting materials that not only meet production specifications but also contribute to the sustainability goals of modern manufacturing practices.

Future Trends in CNC Turning Technology and Its Impact on Modern Manufacturing

The future of CNC turning technology is poised for significant advancements that promise to reshape modern manufacturing. One key trend is the integration of artificial intelligence and machine learning into CNC turning processes. By harnessing these technologies, manufacturers can achieve higher precision, optimize production schedules, and reduce material waste. Intelligent systems can predict tool wear and maintenance needs, leading to increased uptime and efficiency in manufacturing environments.

Moreover, the advent of smart factories is revolutionizing CNC turning operations. The Internet of Things (IoT) enables machines to communicate seamlessly, providing real-time data analysis and insights into production performance. This connectivity allows for agile manufacturing practices, where adjustments can be made instantly based on demand fluctuations. As companies adopt these innovative technologies, we can anticipate a more streamlined production process with the capability to adapt swiftly to customer needs and industry shifts.

Additionally, sustainability is becoming a focal point in CNC turning technology. Manufacturers are increasingly looking for eco-friendly materials and processes, leading to a rise in the development of energy-efficient CNC machines and techniques. These advancements not only minimize environmental impacts but also align with global sustainability goals, ultimately steering the industry towards a more responsible future. The interplay of these trends will undoubtedly define the landscape of modern manufacturing in the coming years.